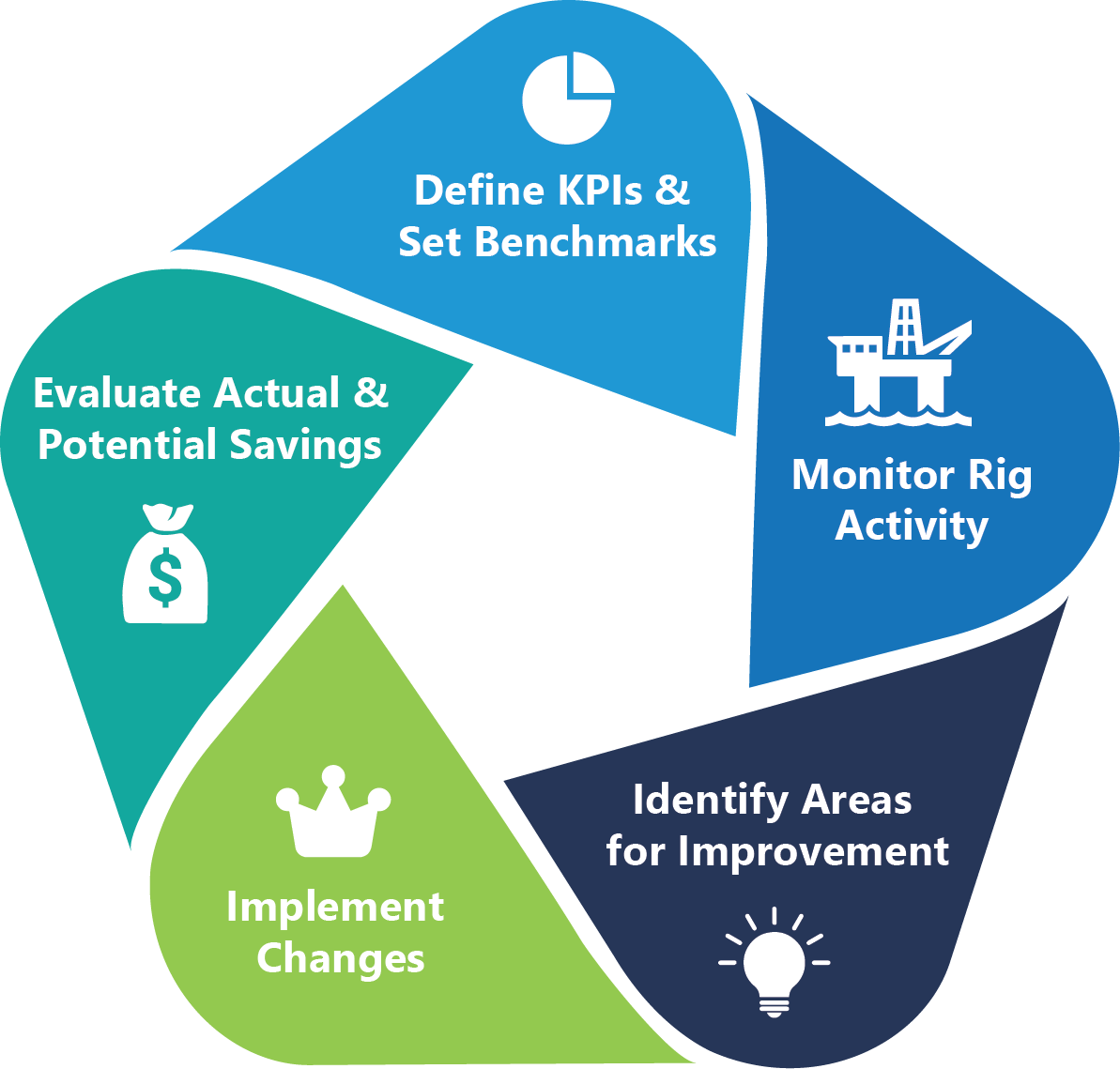

Continuous improvement for optimal performance

Powerful Analysis of Rig Performance for Real Cost Savings

Operators are constantly looking for ways to drill more efficiently and safely while lowering their overall well costs. Identifying gaps in performance and Invisible Lost Time (ILT) can be challenging. And understanding the reasons behind these gaps and inconsistencies so you can improve is almost impossible without the right set of tools.

RigMetrix™ (RMX) is an analytics solution for measuring and improving drilling, tripping and casing performance. It offers operators with actionable insights to improve operational efficiency across the rig fleet. With over 150 KPIs, operators can monitor key operations in a user-friendly, web-based application. PetroVue allows wells engineers to compare metrics between sections, runs, crews and regions and identify optimization opportunities in just a few clicks.

The result? Reduced well construction time and lower costs.

Solution Highlights:

- Accurate rig state detection – Accurate rig state detection is at the core of the RigMetrix™ solution. This automated process inputs sensor signals in real-time to identify over 25 major rig activities.

- KPI dashboards – Create multiple dashboards to analyze rig operations. Each dashboard can be easily customized with widgets to create useful views for engineers and rig crews.

- Filters, groups and aggregates – Use Hole sections, BHA Runs, Rig Crews and other metadata along with in-built aggregate functions such as averages and percentiles to perform in-depth analysis of operations.

- Reporting – Create 24-hour, end of section and end of well reports.