Upstream data management is a complicated process and getting it right is critical. Logs and reports composed using raw real-time or static data are constantly being generated and distributed. Unpicking the strands is not a trivial task. Each contractor has their own database which grows minute by minute – throw in duplicate reports and inaccurate data, and the result is not a clear data lake but a murky swamp!

Evolution of Real-Time Monitoring

Long gone are the days of hand-written reports and paper log copies being faxed or hand-carried from the wellsite. In addition to the time taken, delays, lost-data and guesswork were common-place. While the ‘low-hanging fruit’ major hydrocarbon deposits were being discovered, this could be somewhat overlooked. As the search ventured further offshore to remote regions and expenditure grew exponentially, accuracy, trustworthy and real-time data became essential.

Not long ago, the wellsite geologist and drilling supervisor worked independently at the rig site, relying solely on their own judgment backed by their experience in a particular geological play. It was crucial to have experts on-site; specialists in carbonates, pre-salt, or more recently, deep-water and HP/HT environments. This presented a couple of challenges. The operator might have a limited pool of staff with the required experience and then there was the coordination of getting these people to the rig site.

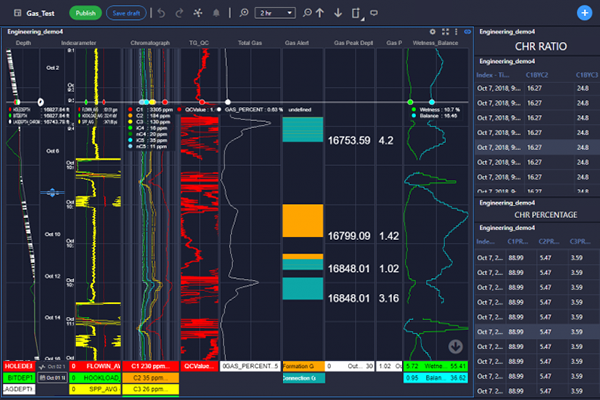

In many ways, Real-Time Operations Centers (RTOCs) solve the people challenge. Geologists, drilling and performance engineers (often from service contractors) are now embedded within the subsurface team. Experts can be quickly summoned to review and act upon real-time data and reduce Non-Productive-Time (NPT). The technology allows experts to monitor many wells located all around the globe at one time. Aided by automated alert tools such as MBE, productivity has increased even further. The advent of real-time notifications now means being able to focus on what is pertinent, without having to perform continuous manual checks.

Remote Operations - No Panacea

Traditionally, there are two information hubs for rig data: the wellsite geologist and the operations geologist. They function as the two checkpoints through which data must pass and where it can be quality-controlled. Since real-time data transmission developed, the flood gates have opened. Anyone (with the correct access) can log into an internet server and see what is happening on the rig.

With volumes of data from the rig mushrooming ensuring data is complete, within range and properly displayed is essential. Catching incorrect data should be done as close to the point of acquisition as possible. This is something that our CTO David Johnson dives into in the Digital Oil and Gas Podcast – explaining how we monitor the quality of the data which runs through Petrolink.

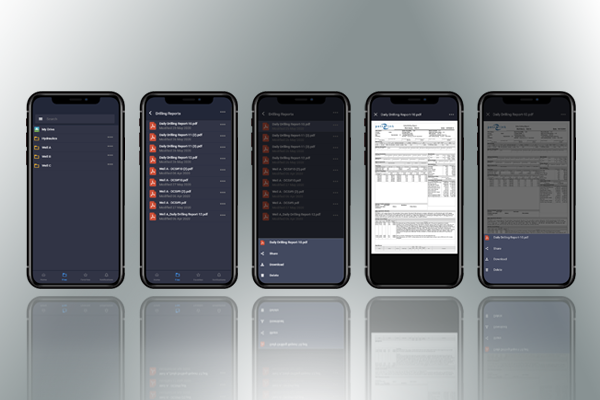

Out of The Office

The era of mobile on-the-go decision-making has been with us for some time. Data can be streamed to smartphones, tablets, or any other internet-connected device. This allows the subsurface team to monitor the well in real-time no matter where they are. This means that well issues can be discussed with the data to hand, even when in remote locations.

Today, working remotely brings many benefits but there is the real danger that siloed working may re-emerge. When people are alone and physically separated, there is the distinct possibility that subsurface departments could go back to relying on just one or two staff member’s interpretation.

This is where a real-time collaboration tool like Impact (released early this year) comes in. It brings real-time chat together in a series of customizable channel groups. Where it goes beyond the existing chat systems, is the integration of real-time chat with the ability to tag well events. These can then be analyzed post well and provide a future record for later development drilling.

In an age of budget constraints and travel restrictions, the need to access real-time data has dramatically increased. While it is tempting to imagine a future where people are no longer required to be physically present at the rigsite. The reality is likely to one of augmentation by technology, complimenting expert knowledge of the nuances of rig equipment and systems.

Digital Rigs

How different is a rig today from one 30 years ago? Equipment such as BOPs, pumps, and top-drive systems are generally the same and are operated by personnel on site. A fully digital ecosystem at the wellsite is yet to be realized.

As a vendor-neutral data management provider, the team here at Petrolink have been instrumental in connecting systems at the rig, linking them back to the office teams- breaking down data silos. This has enabled a greater number of people to be involved leading to more effective decision making which has a material impact on our client’s bottom line every single day.

There has been a concerted effort across industry by operators, services companies and technology providers to close gaps in the data pipeline. Initiatives driven by the Energistics community which provided a common language- WITSML and more recently the Open Group’s OSDU (Open Subsurface Data Universe) of which we are a proud member will be integral to developing the energy platform of the future.

A Paradigm Shift

Emerging technologies like the permission blockchain and smart contracts could form part of the solution. The hashing encryption of blocks provides an immutable auditable trail. Beyond that, they enable alerting of all parties at the rig or office of status changes automatically and simultaneously.

As we have seen, disruptive technology, such as cloud computing, has radically changed the industry over the last four decades. From simple additions like email and VOIP calls, to high bandwidth real-time feeds that provided the lifeblood that fuel RTOC’s. At Petrolink, we have driven these leaps forward. By proactively developing industry data standards, technology and analytical tools, our data scientists continue to look to the challenges of tomorrow. Collectively, the industry has come a long way, but the story does not end here there is still much exciting work to be done.